My older sister, Daniella Muise, was the first person in our family to go to college. She is an example of how higher education can change your life and the reason I pursued a career in engineering. After she was hired as an engineer at ExxonMobil, I followed in her footsteps. I studied metallurgical and materials engineering and completed three internships with the company. Then I was hired full time, providing material support for our Baytown, Texas, complex.

In my first role, I managed equipment reliability. I saw my work as a key factor to support safe and environmentally sound operations – which are two things I’m really passionate about. Since then I’ve been drawn to improving the way we do things, for our own employees, for our customers and for society. This was especially tangible when I learned how our technology and products can make it easier for society to recycle plastics. So when ExxonMobil started exploring advanced recycling, I jumped at the chance to join.

Our company is integrated into the value chain around plastics. We’re close to the manufacturers who make the plastic products that consumers use on a daily basis. We can identify potential partners in business and government, strengthen new and existing relationships, and work together to develop solutions to the complex problems we all face. And, we believe the scalability of advanced recycling makes it one of the most exciting solutions out there.

The ultimate goal of advanced recycling is to help society recycle a greater share of the products we use every day – instead of throwing them away. By making advanced recycling a scalable solution that can be replicated globally, we can increase the amount of plastic material that can be made into new products and reduce plastic waste.

We see advanced recycling complementing the current forms of conventional recycling – both solutions are needed. Advanced recycling expands the types of plastics that can be recycled, as well as what they can be recycled into. Currently, conventionally recycled plastic is limited in its ability to be used for food packaging, for example. Advanced recycling doesn’t have those limitations because it returns plastic to its molecular building blocks.

At ExxonMobil, we have a lot of smart people who are passionate about sustainability and want to play a role in helping the world recycle more. And we’re fortunate in that we have a lot of groundbreaking projects planned – from Baytown, Texas to Notre Dame de Gravenchon, France.

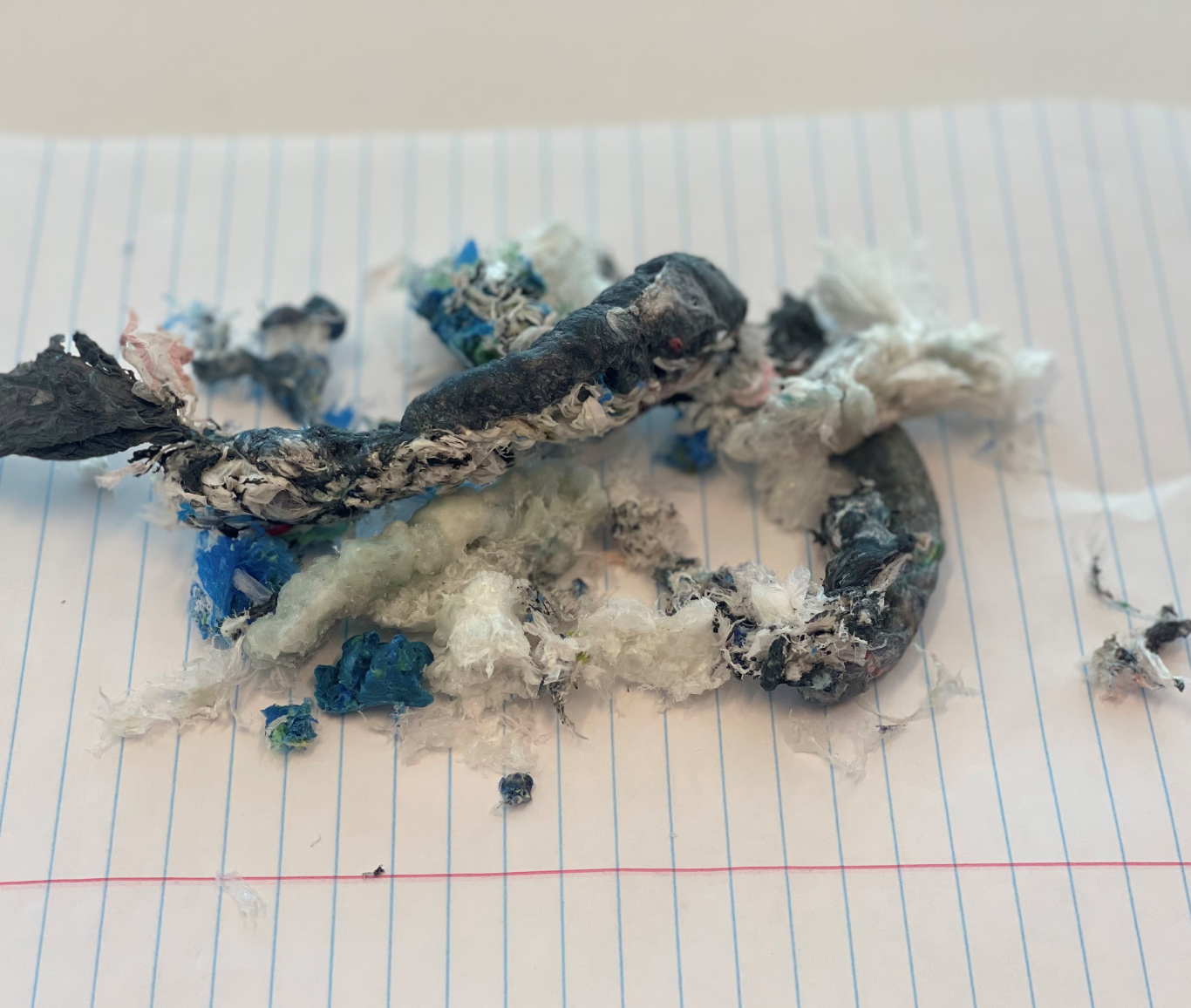

My role is to find sources of plastic feed for those projects – plastic that has reached the end of its life and would normally be considered waste – like the bubble wrap used to mail a product you bought online or the pouch that holds my daughter’s favourite snack mix. While there’s no shortage of plastic being put into bins, getting it to our facility requires some work. Essentially, I’m helping develop supply chains and infrastructure to make that easier – to make sure that the plastic we throw in the recycling bin can be remade into new valuable products we use every day.

As my career has developed with ExxonMobil, I knew that I wanted to grow into being a part of advancing sustainable solutions. The work is fast-moving and challenging, and we don’t have all the answers yet – but it’s exciting to be on the leading edge of new developments across this space. I sometimes reflect on just how far we’ve come over the last year and a half, and that renews my resiliency.

My role in advanced recycling is unlike anything else I’ve done in my career. Yet, it’s the perfect combination of my passions in sustainability and equipment reliability – both areas I’ve been exploring since I started at ExxonMobil almost 20 years ago.